The Structural Ironworker

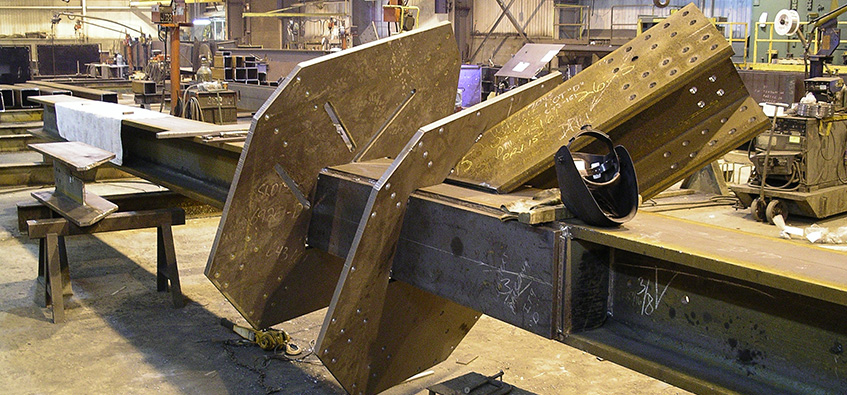

The sight of a massive steel girder being hoisted into the sky by a crane is a familiar one in Canada’s cities. What happens when it gets there is the job of the ‘Structural Ironworker’. Using engineering blueprints, specialized training and muscle, these Ironworkers position steel girders and beams with amazing precision, and then bolt them securely in place.

Most of this work is performed by hand, using tools like the legendary Ironworker’s ‘spud wrench’. And those cranes in the sky? They put those together, too. Structural ironwork is a job few dare to do, but building a better world depends on it.